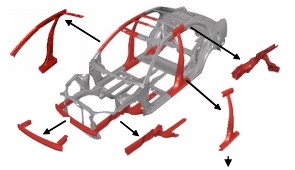

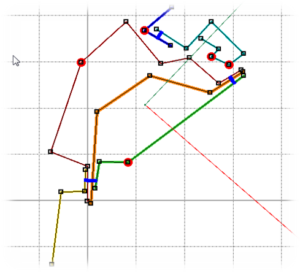

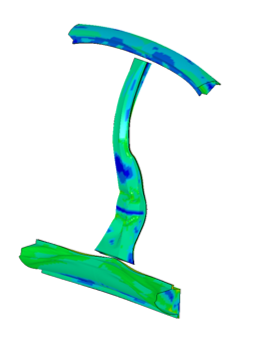

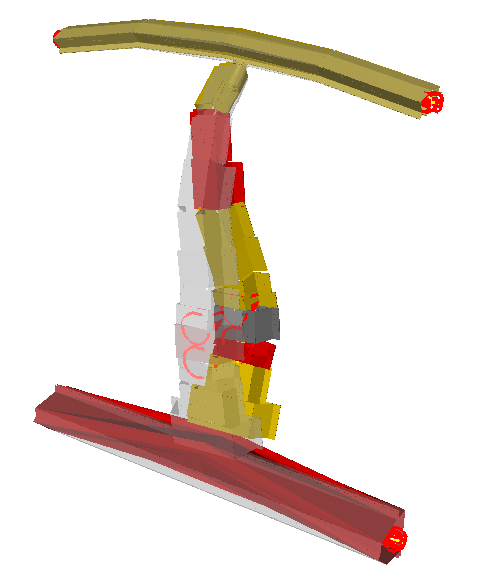

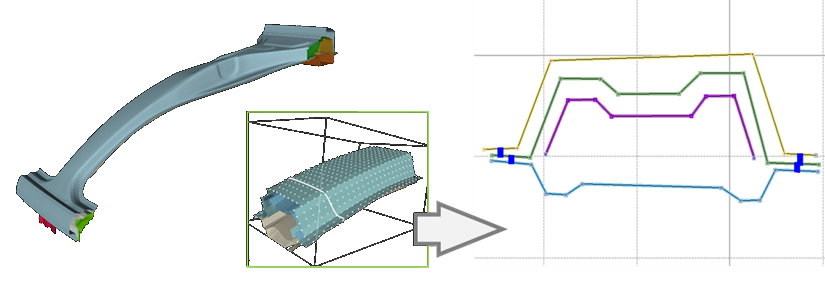

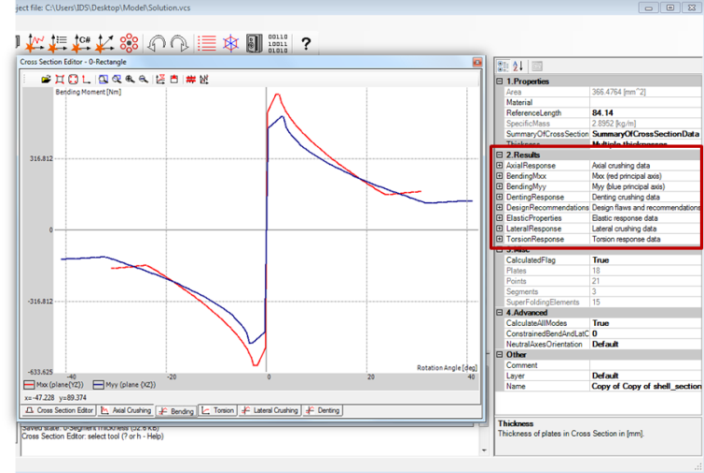

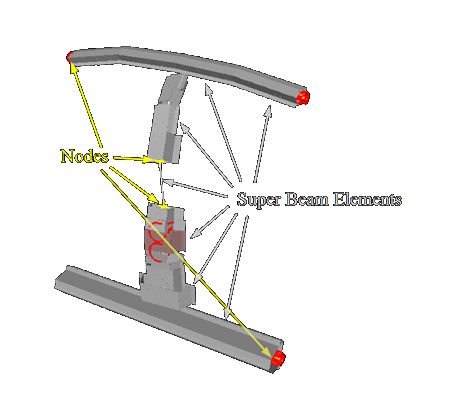

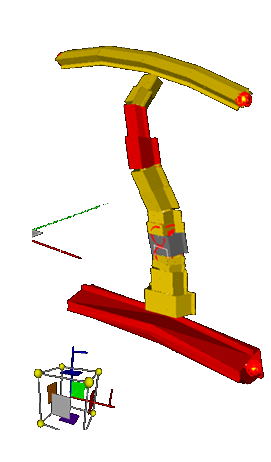

Visual Crash Studio (VCS) is a unique tool for crash analysis at the pre-design stage of vehicle development. The advantage of the VCS software is the possibility of making independent calculations at various stages of the modeling. Initial analyses refer to the cross-sectional level of the model. Subsequent calculations can be performed as each sub-assembly of the structure is developed. In the case of a simple model, calculation time should not exceed several dozen seconds. For complex design, the time required for calculation should not exceed several minutes. In consequence, the Visual Crash Studio environment enables constant and quick verification of the model until the final simulation of the complete assembly is achieved.

VCS specific workflow characterized by a simplified modeling method assures easy application of design modifications. The approach of parallel modeling and analysis is most suitable for the VCS workflow. The efficiency of such a line of a design process is insured due to the short computation time (seconds to minutes compared to hours in FE solvers). In consequence, VCS is recommended to be used in the pre-design stage of product development, where the possibility of fast verifications and adjustments of the designed structure is essential.

Visual Crash Studio does not compete with FE methodology solvers but complements them. It gives the possibility to develop, verify and optimize a vehicle concept with accurate crash analysis at the early stage of the structure development process, thus avoiding time and cost–consuming major modifications in later stages of vehicle development. VCS calculation model can emerge from scratch or be based on detailed data obtained from FEM solvers.